Brew Day: BBOC Honey Porter

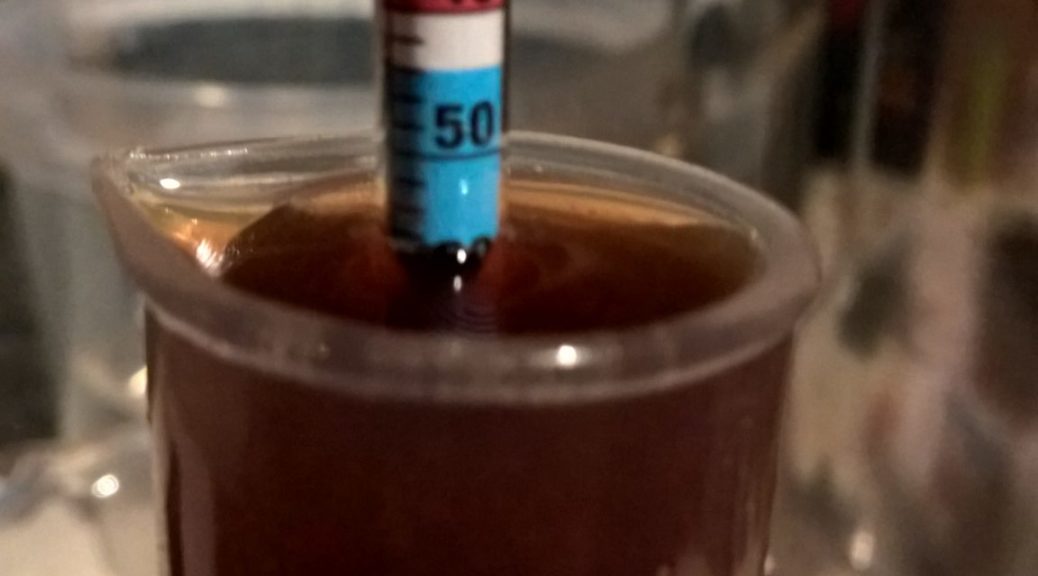

At the time of bottling my BBOC Vanilla Porter, I was really worried that what I was tasting wasn’t very nice. So, I decided to brew another porter for the BBOC competition just in case… This Honey Porter is based on Greg Hughes’ recipe from his Home Brew Beer book, adjusted for my equipment & volume. 3.71 kg Maris Otter Malt (Muntons) (5.9 EBC) Grain 1 65.1 % 0.62 kg Caramalt (Muntons) (29.6 EBC) Grain 2 10.8 % 0.50 kg…